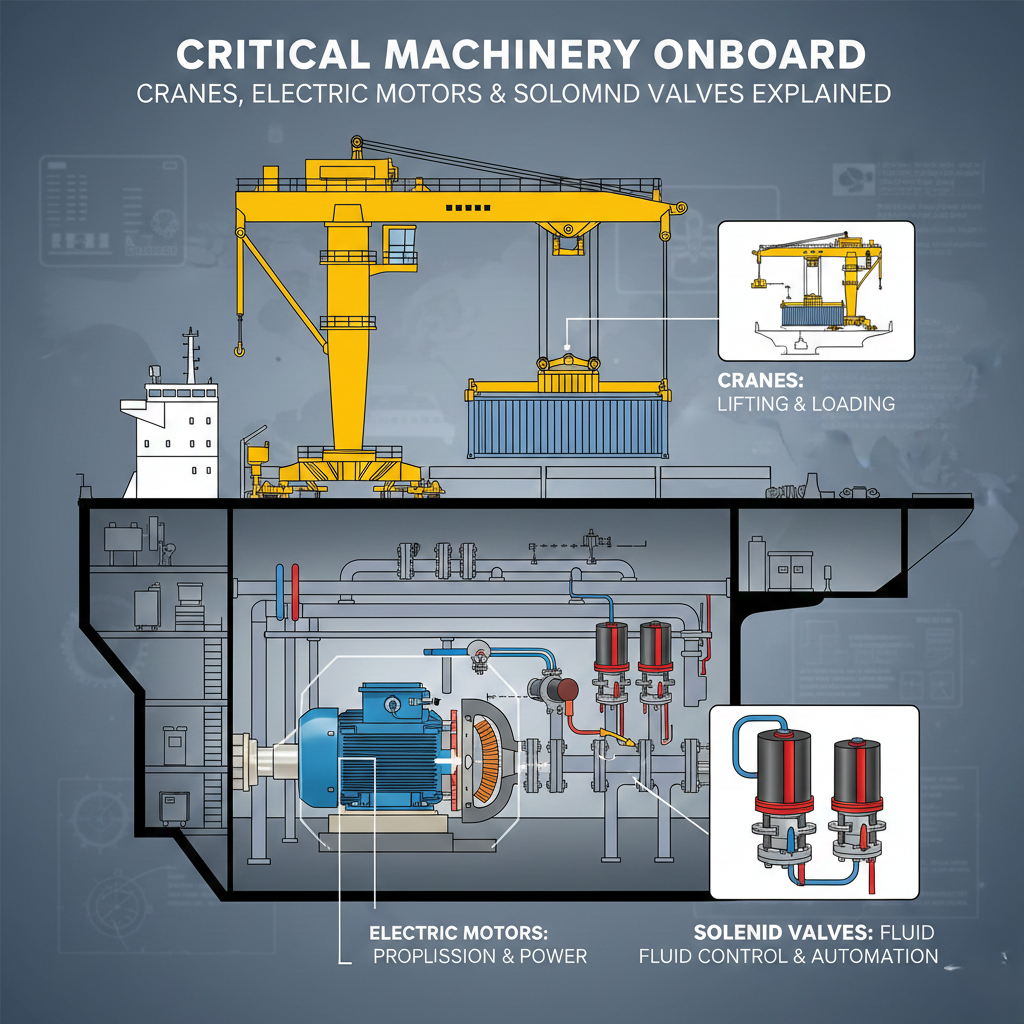

CRITICAL MACHINERY ONBOARD: CRANES, ELECTRIC MOTORS & SOLENOID VALVES EXPLAINED

Efficient vessel operations rely on

the seamless performance of critical onboard machinery. Shipboard cranes,

electric motors, and solenoid valves are central to cargo handling, engine room

operations, and automation systems. Proper understanding, maintenance, and

access to certified spare parts are essential for safe, reliable, and

uninterrupted maritime operations.

Solanki Ship Care, a trusted marine

supplier, provides marine-certified spare parts and technical assistance,

ensuring vessels maintain peak machinery performance and comply with industry

standards.

1. Shipboard Cranes: Types &

Applications

Cranes onboard play a pivotal role in handling cargo, provisions, and heavy

machinery. Their design and placement vary depending on purpose.

Types of Cranes:

• Provision Cranes: Small cranes used for supplies, provisions, and

light equipment during port operations.

• Engine Room Cranes: Overhead or gantry cranes used for lifting heavy

engine components during maintenance.

• Deck Cranes: Used for cargo loading/unloading; crucial for vessels

without shore-based handling facilities.

Why They Matter

Reliable cranes ensure safe cargo handling and reduce operational delays. Regular

inspection, load testing, and lubrication prevent failures and maintain

operational efficiency.

2. Electric Motors: Powering Vessel

Operations

Electric motors are integral to pumps, fans, compressors, winches, and

auxiliary machinery, supporting both manual and automated operations onboard.

Key Functions:

• Drive pumps, compressors, and ventilation systems

• Power winches and steering mechanisms

• Facilitate vessel automation and control systems

Why They Matter

Properly maintained motors ensure energy-efficient operations, reduce downtime,

and support safety-critical systems. Regular insulation checks, bearing

lubrication, and vibration monitoring prevent unexpected failures.

3. Solenoid Valves: Small

Components, Big Impact

Solenoid valves control the flow of fluids such as fuel, oil, water, and air

across vessel systems, enabling automated and safe operation.

Key Applications:

• Fuel and lubrication systems

• Ballast and fire-fighting automation

• Engine start/stop systems

• Remote operational control and safety shutdowns

Why They Matter

Reliable solenoid valves are critical for automated systems and emergency

functions. Regular cleaning, coil testing, and ensuring fluid purity prevent

malfunctions and safety risks.

4. Common Failure Points &

Preventive Maintenance

Cranes: Wire rope wear, hydraulic leaks, motor overheating, structural

fatigue

Motors: Bearing damage, insulation failure, loose connections, dust

ingress

Solenoid Valves: Coil burnouts, blockages, seal wear, overheating

Preventive Measures:

• Routine inspections and load testing

• Lubrication and cleaning schedules

• Timely replacement of worn components

• Vibration and electrical monitoring

5. Solanki Ship Care: Trusted

Supplier & Technical Support

Solanki Ship Care ensures vessels have access to certified marine spare parts

and expert guidance.

Our Key Services Include:

• Supply of marine-certified crane components, electric motors, and solenoid

valves

• Technical assistance for machinery troubleshooting and maintenance

• Timely delivery of critical spares across Indian and international ports

• Expert advice on preventive maintenance and compliance with marine standards

Whether it’s cargo handling systems,

engine room machinery, or automation components, Solanki Ship Care guarantees

reliable, high-quality parts and technical support.

Final Thoughts

Critical machinery onboard cranes, electric motors, and solenoid valves are the

backbone of efficient maritime operations. Understanding their functions,

maintaining them regularly, and sourcing certified spares from trusted

suppliers like Solanki Ship Care ensures safe, uninterrupted, and compliant

vessel operations worldwide.